A female boss from Nantong who sells cardboard boxes wins the only national industry award, with an annual income exceeding 200 million.

Publish Time:

2025-05-13

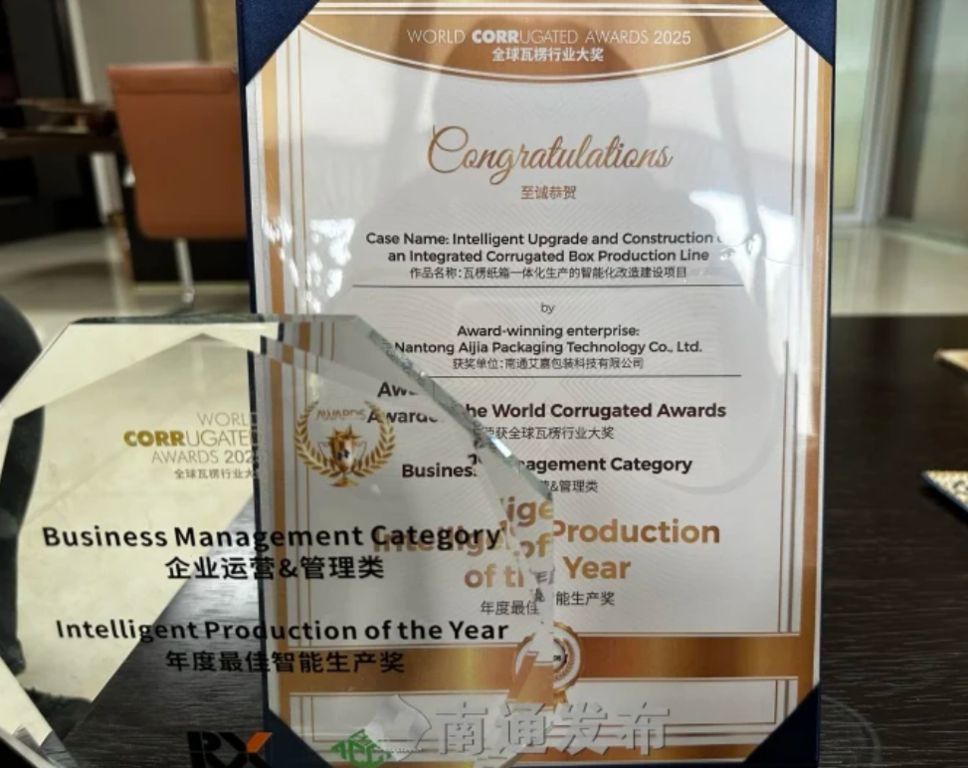

Recently, Aijia Packaging Technology Co., Ltd.'s "Intelligent Transformation and Upgrading Project for Integrated Production of Corrugated Boxes" won the 2025 WEPACK Global Corrugated Industry Award for Best Intelligent Production of the Year, the only one in the country.

Recently, Aijia Packaging Technology Co., Ltd. Its "Intelligent Transformation and Construction Project for Integrated Production of Corrugated Cartons" won the 2025 WEPACK Global Corrugated Industry Award for Best Intelligent Production of the Year ,being the only one nationwide.

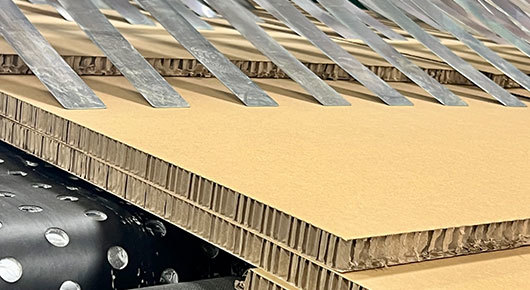

Entering the company's intelligent workshop, from the raw material warehouse to the loading, printing, cutting, packaging, stacking, and warehousing processes, there is no manual handling or forklift transfer. Each process is connected by a 5G logistics network. Handling is done by robotic arms, with a small number of workers patrolling and checking the production equipment. The entire factory covers an area of 100,000 square meters, and a cardboard production line runs 250-280 cartons per minute, requiring only two workers. 。

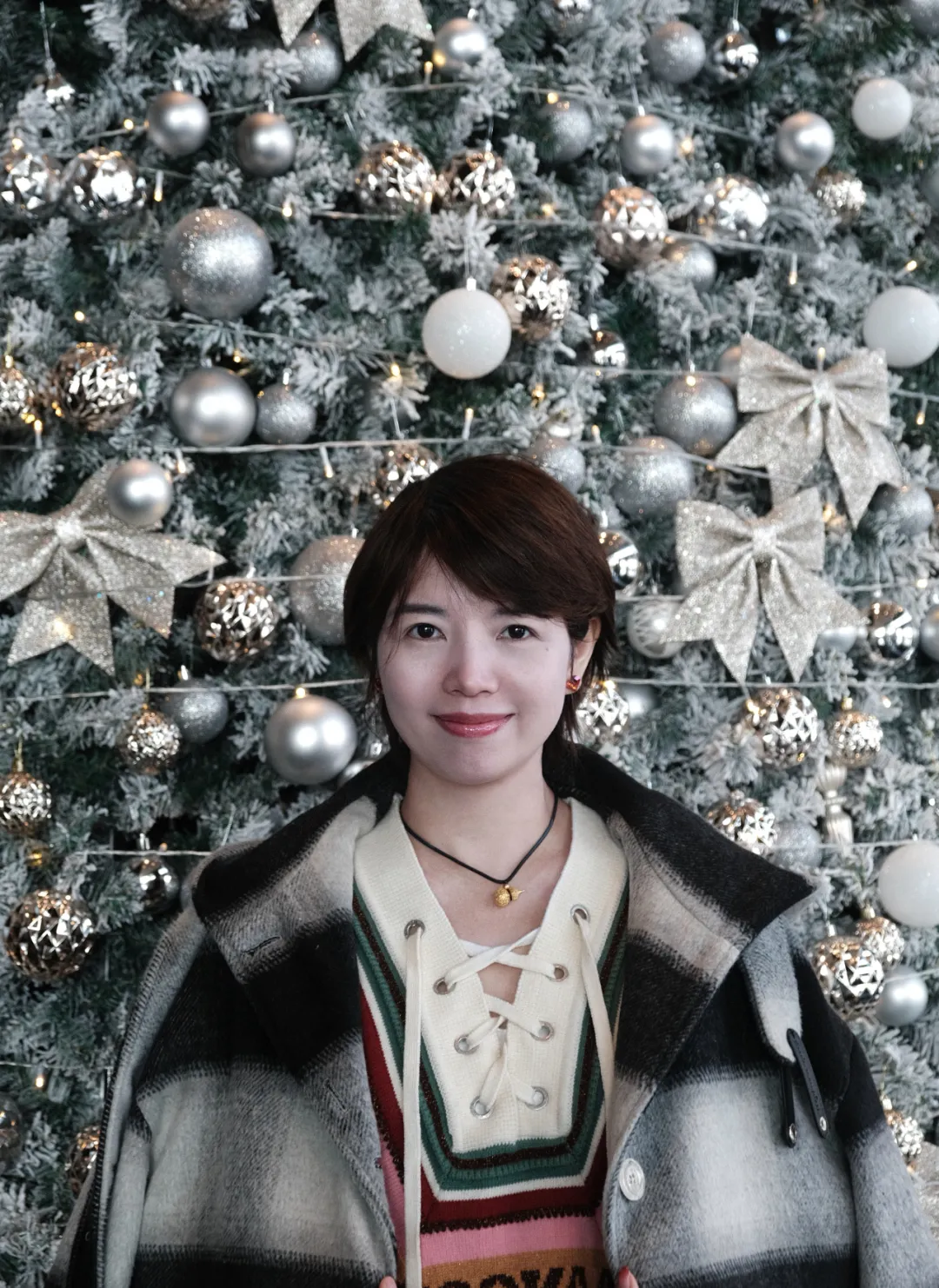

When Executive Vice President Yu Yingjun introduced this, her expression was quite proud. She said: "Aijia is like my child. Every time I see a truck full of products heading towards customers, I unconsciously feel a little worried, both pleased that they are about to realize their value, and with the apprehension of a guardian, hoping that they will be recognized."

Yu Yingjun has a neat and refreshing short haircut, and her gentle smile hides an unwavering tenacity. She is logical and articulate. In the traditional impression, "Yingjun" is always seen as a male name, but Yu Yingjun's existence has broken through this gender-stereotyped world.

The Pains of Transformation

Tongzhou District, as a global textile and home furnishing distribution center, has a huge demand for cardboard and paperboard.

Yu Yingjun

In 2003, Yu Yingjun's husband, Ma Bing, keenly captured this market prospect and founded Aijia Packaging. Initially, the company mainly supplied paperboard to the surrounding home textile market. At that time, the home textile business accounted for more than 70% of the company's share. However, with increasing market competition, the profit margins in the paperboard industry became increasingly thin, and customers' demand for product quantity and personalization continued to increase. Traditional small workshop-style production could no longer meet the needs of the company's development.

To cope with industry involution and market competition, in 2020, Aijia Packaging embarked on a transformation journey, focusing on automated production, upgrading from paperboard production to carton processing, and gradually undertaking orders from large enterprises such as Fortune 500 companies. The company has built a lights-out production system from order placement to logistics ,relying on 5G interconnection and Industry 4.0 technology to create a unique automated production system. It is thanks to this system that Aijia Packaging won the global corrugated industry award and is in a leading position in the industry.

Regarding the difficulties of transformation, Yu Yingjun said that the huge initial investment of nearly 100 million yuan for automation put a lot of pressure on private enterprises, and there were technical challenges in connecting various machines and equipment to form an integrated system. However, her husband, Ma Bing, is a technology-oriented entrepreneur. Under Ma Bing's leadership, in March 2022, a fully automated carton production line was officially put into production. After completing the initial integration and achieving mass production, Ma Bing did not slack off. He continued to optimize and improve in subsequent production, ultimately overcoming the difficulties and forging a path of high-quality development through automated transformation.

In 2023, Aijia Packaging introduced China's advanced Super 400 intelligent corrugated line, becoming the first to achieve 250 meters/minute uninterrupted order change, with a maximum speed of 350 meters/minute. Through the development of ERP/MES software, production management system, entire line control, and temperature control system, seamless connection is achieved to ensure efficient operation of the entire factory.

Currently, Aijia Packaging has one 280-400 high-speed corrugated paperboard production line and one 240-100 honeycomb paperboard production line, with a daily output of more than 600,000 square meters of various grades of paperboard and 200,000 square meters of honeycomb paperboard. The carton workshop, built according to 4.0 standards, has a top-level digital production line, supplying more than 200,000 cartons per day. It has been included in the supply chain of many Fortune 500 companies, including Hengli Chemical Fiber, Longi Green Energy, Jin Hongye, Forlight Group, Xinyi Glass, and Shangling Electric. In 2024, sales reached 220 million yuan, and this year's sales are expected to reach 300 million yuan.

Learning? Learning!

Around 2010, Yu Yingjun was a leader in the import and export wine industry, serving as the national general agent for Château Kirin in France. She visited Bordeaux wineries in France to learn about grape growing and winemaking. With excellent products and brand marketing capabilities, in 2013, the company she founded was featured on Jiangsu Television's interview program "Slightly Intoxicated Bordeaux."

Yu Yingjun

However, at that time, her son was entering elementary school, a crucial stage of growth. To ensure that her child could receive better family education and companionship, Yu Yingjun and Ma Bing, after careful consideration, made an important decision ——Yu Yingjun resolutely gave up her thriving wine business and chose to return to her family.

Modern economics research has confirmed that the labor of housewives, if calculated according to market value, has a considerable economic contribution. Housewives, as an important role in the modern social division of labor system, their professional attributes should be fully recognized. Yu Yingjun maintained the stable operation of the family, a basic social unit, providing strong logistical support for other family members.

Although her life radius temporarily shrank, Yu Yingjun never allowed daily chores to wear down her ambition.

She practiced the concept of lifelong learning, enthusiastically studying various types of knowledge, obtaining qualifications in intermediate economist, preschool education, and psychological counselor, and also continued to learn foreign languages, ensuring that she did not fall behind society.

During this period, her husband Ma Bing's Aijia Packaging was in a period of rapid development. Whenever Ma Bing came home to discuss the company's development plans, technical challenges, or business dynamics, Yu Yingjun would listen attentively and actively participate in the discussion.

This continuous interaction allowed her not only to have a comprehensive grasp of the company's business situation but also to gain a deeper understanding of the company's core technologies, management philosophy, and cultural values. This subtle accumulation laid a solid foundation for her return to the workplace and participation in corporate management.

Astonishing Growth Speed

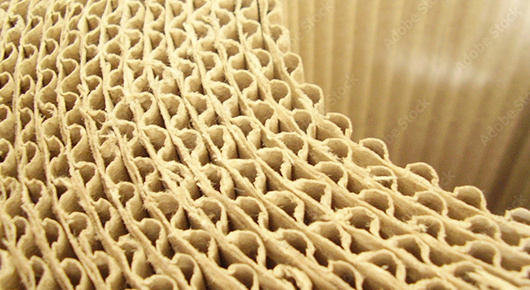

In 2024, with the launch of the honeycomb cardboard project, Aijia Packaging entered a new period of transformation. Ma Bing urgently needed a capable assistant, so Yu Yingjun returned to the workplace to take charge of the honeycomb project, helping him manage affairs and allowing him to focus on core work such as product updates and technological reforms.

When lifelong learning becomes instinct, so-called cross-border challenges are merely a natural extension of accumulated wisdom.

When first exposed to enterprise operations management, Yu Yingjun faced enormous challenges. Previously engaged in brand marketing and promotion, focusing on market trends and brand exposure; factory management is entirely different, emphasizing internal integration, personnel efficiency, equipment operation, and customer service loops—tedious and complex.

In fact, the professional barriers in most industries do not stem from the arts/science divide, but rather from whether an individual can cultivate deep expertise in a specific field. Initially, Yu Yingjun knew nothing about machinery and equipment, but she with the belief of "a slow bird should take an early start; diligence can make up for lack of talent," diligently studied technical manuals, consulted frontline workers, and participated in industry training, gradually adapting to her new role and steadily advancing on the path of factory management.

Facing these challenges, Yu Yingjun summarized: "The difficulty of factory management lies in the meticulous control of details and high degree of team collaboration, but every breakthrough brings a new sense of value."

In just one year, she demonstrated an astonishing growth rate. This rapid improvement stems from her past knowledge reserves and experience accumulation, but also from her extraordinary efforts over the past year. It is foreseeable that if she continues to maintain this learning ability and professional dedication, after five or ten years of continuous cultivation, her accumulated industry knowledge and problem-solving abilities will surely surpass the limitations of her initial academic background, becoming a true corrugated paper expert.

A soul that never stops on the path of knowledge will eventually transcend barriers and prove itself. ——From the vineyards of Bordeaux, to the choices between the kitchen, day and night, and love, and then to the limited space of factory equipment drawings, Yu Yingjun used three career transformations to interpret the underlying tenets of a high-level professional woman: True excellence is never limited to a single track, but is forged in the switching of roles, cultivating multi-dimensional competitiveness.

Making every effort to pave the way.

The transformation has yielded significant results, but Yu Yingjun remains clear-headed. Although the company's single production line capacity is among the best in the industry, due to the high industry concentration and numerous large enterprises, there are still considerable challenges in standing out in the fierce market competition.

"As a 'sandwich layer' between the raw paper supplier and the customer, the company lacks bargaining power in both upstream and downstream—raw paper prices are dominated by suppliers, and in the face of large customers, we can only meet their needs by reducing costs and increasing efficiency," Yu Yingjun analyzed.

She stated that in the future, Aijia Packaging will Artificial intelligence and cost reduction and efficiency improvement continue to explore. On the one hand, simplifying and optimizing internal enterprise processes to reduce costs; on the other hand, promoting automated technological transformation. For example, with the development of artificial intelligence in the future, it is expected to achieve more effective control of equipment for product sorting and quality control, improving production efficiency and stabilizing product quality.

Currently, in the three major development directions of "automation, greening, and high-end," Aijia Packaging has made significant progress in automation and greening. In terms of high-end, the company is also actively trying to break through, considering how to break the inherent concept of corrugated paper as merely packaging, achieving innovation in high-end brands and packaging design.

At present, with the industry consensus on lightweight, green, and recyclable packaging, thick honeycomb cardboard is becoming an ideal material for many industries with its unique advantages "replacing wood with paper" and "replacing plastic with paper." From honeycomb furniture, honeycomb pallets, heavy-duty cartons to honeycomb villages, thick honeycomb cardboard perfectly meets the needs of the green transformation era—Yu Yingjun is in charge of this area.

"Aijia Packaging introduced honeycomb board and honeycomb carton production lines at the beginning of 2024 and officially put them into production in June. Compared with traditional corrugated products, honeycomb products can save 20-30% of paper costs, and have high production efficiency and good compressive strength, which can drive enterprises in the photovoltaic, home appliance, and food industries to gradually switch to honeycomb packaging. Although honeycomb packaging has technical barriers in process control, both Mr. Ma and I are confident that Aijia Packaging can maintain its leading position in the industry nationwide through its strict requirements for technology and quality." said Yu Yingjun.

Along the way, Yu Yingjun has witnessed Aijia's breakthroughs in technological innovation, building confidence through customer recognition. In the future, she will also work with the Aijia people, with the patience to accompany Aijia Packaging through cycles, making every effort to pave the way for it.

Real-time News

Recently, Aijia Packaging Technology Co., Ltd.'s "Intelligent Transformation and Upgrading Project for Integrated Production of Corrugated Boxes" won the 2025 WEPACK Global Corrugated Industry Award for Best Intelligent Production of the Year, the only one in the country.

On September 9th, reporters learned from Chuanjiang Town, Tongzhou District that Nantong Aijia Packaging Technology Co., Ltd. won the 2025 WEPACK Global Corrugated Industry Award for its "Intelligent Transformation and Construction Project of Integrated Production of Corrugated Cartons."

Nantong Aijia Pack Tech Innovations Co., Ltd.

Phone:0513-86330889

Email:12105482@qq.com

Address: No. 211 Wenzhou Middle Road, Chuanjiang Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright: Nantong Aijia Pack Tech Innovations Co., Ltd.