Carton production transitions from manufacturing to intelligent manufacturing – Aijia Packaging Company invested nearly 100 million yuan in technological transformation, achieving paperless order reception, information-based production, digital logistics, and unmanned operation.

Publish Time:

2024-09-12

On September 2nd, nearing noon, inside the production workshop of Nantong Aijia Packaging Technology Co., Ltd., Ma Bing, the company's chairman, was busy debugging equipment. "The newly introduced equipment needs some localized improvements. My technical staff and I have been busy for over ten days, and it's basically fixed in the past few days."

On September 2nd, nearing noon, inside the production workshop of Nantong Aijia Packaging Technology Co., Ltd., Chairman Ma Bing was busy adjusting equipment. "The newly introduced equipment needs some on-site modifications. The technical staff and I have been busy for over ten days, and we've basically finished the modifications these past few days."

Looking around the workshop, there are few workers, yet the production lines are orderly. In the past two years, Aijia Packaging Technology has invested nearly 100 million yuan in technological transformation funds, achieving new breakthroughs in technological innovation. The intelligent packaging project has achieved dark factory production, 5G interconnection, unmanned warehousing, and self-service dispatch. The extensive application of big data and cloud technology has achieved paperless order placement, information-based production, digital logistics, and unmanned operation.

Only 6 workers in a 20,000-square-meter workshop

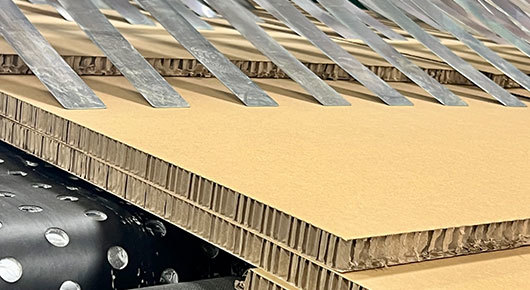

In the common understanding, the cardboard box production industry is a labor-intensive industry with low technological content and a low threshold. However, upon entering Aijia Packaging Technology, the intelligent workshop is refreshing: from the raw material warehouse to the loading, printing, cutting, packaging, stacking, and warehousing processes, there is no manual handling or forklift transfer. Each process is connected by a 5G logistics network, and handling is done by robotic arms. A small number of workers patrol and check the production equipment.

"This is a production workshop that integrates intelligence, digitalization, and information technology." Ma Bing introduced that the workshop is equipped with a complete set of advanced equipment. From cardboard production to carton printing, from internal factory logistics to finished product warehousing, everything is handled by an information tracking system to ensure zero errors.

Aijia Packaging Technology is a local enterprise in Chuanjiang Town, Tongzhou District, established in 2003, covering more than 100 mu (approximately 16.7 acres) and possessing 100,000 square meters of standard factory buildings. "Over the past ten years, the company mainly engaged in cardboard production and sales. With the development of the times and social progress, the company also faces transformation and upgrading. At the end of 2020, I decided to change the original cardboard production model, introduce advanced equipment, and build automated production lines. This is a completely new path, with almost no experience to draw on." Ma Bing said that in the past, a traditional cardboard production line required 300 workers to achieve 300 million yuan in output value, while an automated and intelligent cardboard production line, through seamless data connection to improve interoperability between various equipment and efficient factory operation and decision management, has significantly increased overall efficiency. "The company's workshop of more than 20,000 square meters only has 6 production workers, reducing personnel by nearly half, while efficiency has doubled, truly achieving staff reduction, quality improvement, and efficiency increase."

Connecting 6 pieces of equipment to build an automated production line

On the intelligent carton linkage production line of Aijia Packaging Technology, the reporter saw that stacks of cardboard, after processing, came out of the production line as finished cartons. The entire process requires no manual intervention.

In 2021, the company invested nearly 20 million yuan and successively introduced 6 production equipment, taking the first step in the company's transformation and upgrading. After more than a year of research and development and improvement, in March 2022, a fully automated carton production line was officially put into production. "Previously, the 6 pieces of equipment were all independent. This equipment completed this process, and then workers would handle the transportation and operation before moving to the next process. I had a prototype of automated production in my mind, and combining my experience in the machinery industry, I connected these equipment through logistics and software, resulting in this production line."

Currently, this production line can produce 100,000 cartons in 8 hours, with high speed and quality standards. "If using traditional technology, these 100,000 cartons would require 40 workers to complete, but now only two people can easily achieve this output." Ma Bing said.

To further enhance customer experience and service efficiency, Aijia Packaging Technology has also independently developed a mobile phone App, allowing customers to place orders with one click and monitor the entire production and transportation process. At the same time, it has invested heavily in upgrading the cardboard logistics and transportation system to achieve automated and intelligent transportation and intelligent distribution, allowing products to directly reach the dock for loading, ensuring product quality while saving manpower and transportation costs. The company's high-standard production level has provided strong support for the packaging of products from world-class companies such as Hengli and Midea.

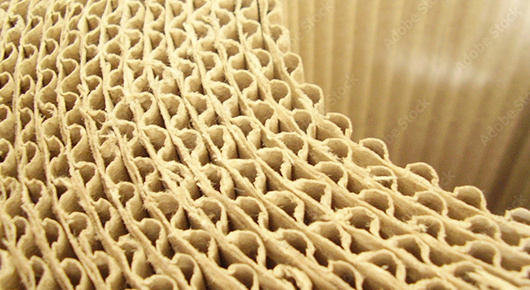

Transformation and upgrading without forgetting green development

While focusing on technology, Aijia Packaging Technology attaches even greater importance to "green" development. With increasing social emphasis on environmental protection, honeycomb cardboard has gradually entered the public eye. Adhering to the low-carbon concept of "technological innovation, green at heart," at the beginning of this year, Aijia Packaging Technology invested more than 20 million yuan to introduce a honeycomb cardboard production line. It is currently in trial production, and after reaching normal production capacity, it can provide 150,000 square meters of honeycomb cardboard per day, increasing sales by 150 million yuan.

Ma Bing introduced that compared with corrugated cardboard, honeycomb cardboard is lighter and stronger. Most importantly, honeycomb cardboard consumes less material. "For example, if I produce one square meter of cardboard according to the same standard, corrugated cardboard consumes 1 kilogram of material, while honeycomb cardboard only needs 0.6 kilograms, saving raw materials and being more low-carbon and environmentally friendly."

Since the trial production of honeycomb cardboard, many industry leaders, including Hengli Chemical Fiber, Longi Green Energy, and Fu莱特玻, have shown strong interest. Longi Green Energy has now fully promoted its use, reducing costs and achieving low carbon, with broad market prospects.

Ma Bing said that to date, Aijia Packaging Technology has built one high-speed corrugated cardboard production line and one honeycomb cardboard production line, with a daily output of more than 600,000 square meters of cardboard and nearly 300,000 finished cartons. In 2023, sales reached nearly 300 million yuan, and taxes paid exceeded 5 million yuan. This year, it is expected to achieve sales of 350 million to 400 million yuan.

Reporters Xu Aiying and Ren Yibin

Real-time News

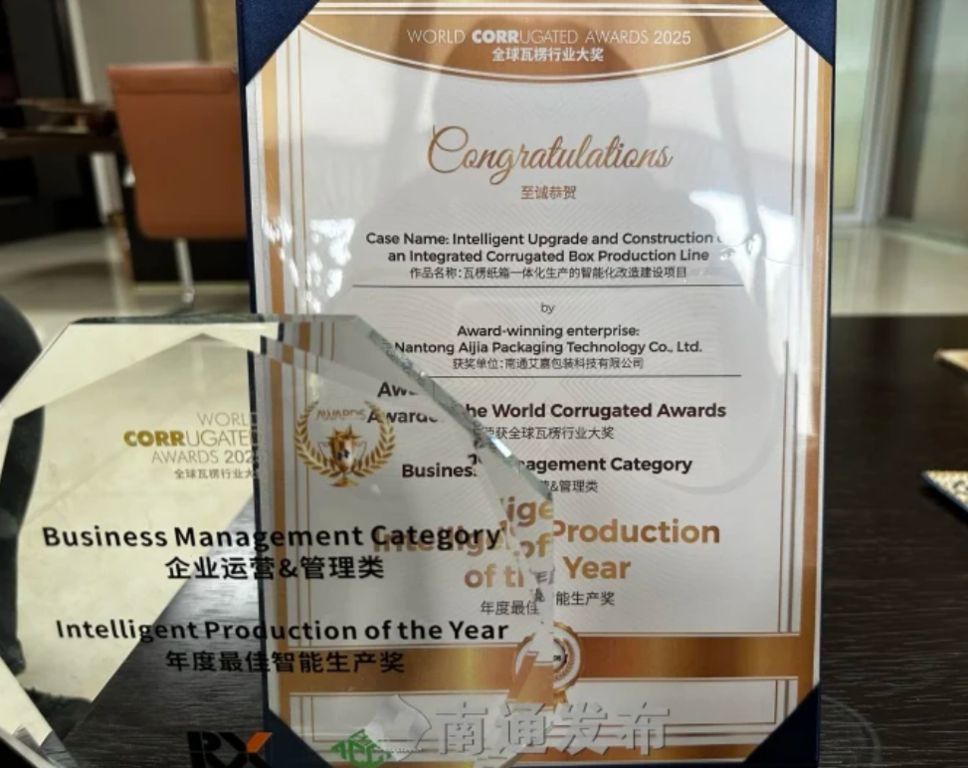

Recently, Aijia Packaging Technology Co., Ltd.'s "Intelligent Transformation and Upgrading Project for Integrated Production of Corrugated Boxes" won the 2025 WEPACK Global Corrugated Industry Award for Best Intelligent Production of the Year, the only one in the country.

On September 9th, reporters learned from Chuanjiang Town, Tongzhou District that Nantong Aijia Packaging Technology Co., Ltd. won the 2025 WEPACK Global Corrugated Industry Award for its "Intelligent Transformation and Construction Project of Integrated Production of Corrugated Cartons."

Nantong Aijia Pack Tech Innovations Co., Ltd.

Phone:0513-86330889

Email:12105482@qq.com

Address: No. 211 Wenzhou Middle Road, Chuanjiang Town, Tongzhou District, Nantong City, Jiangsu Province

Copyright: Nantong Aijia Pack Tech Innovations Co., Ltd.